Over the fall 2025 semester, I worked with an air-breathing electric propulsion system (ABEP) as an undergraduate research assistant in the Underwood lab. With a project deadline set in early December by NRL, I learned how to deliver hardware with urgency.

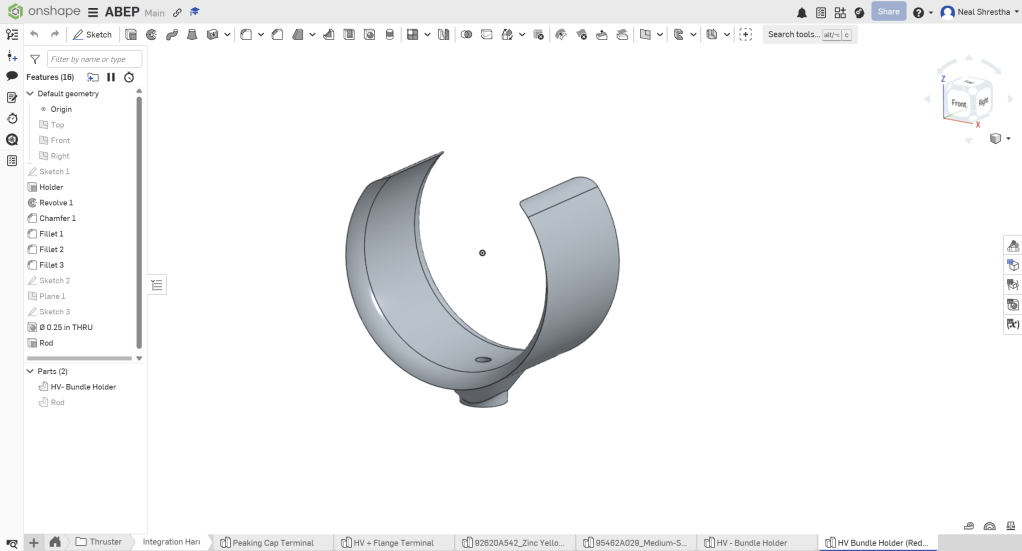

My first assignment was to design holders, stands, and other hardware to assist thruster integration. I took measurements of the real setup and used OnShape to design components.

Next, I worked on the thruster’s power systems. I manufactured 32 high-voltage cables from 12-AWG and ring terminals. These cables (shown below) connected the Integrated Power Module (IPM) to the thruster’s flange. It was critical that we mitigated EMI from these cables, so I used a power drill to create many twists. Additionally, I crimped, soldered, and heat shrunk ring terminals to each bundle’s end.

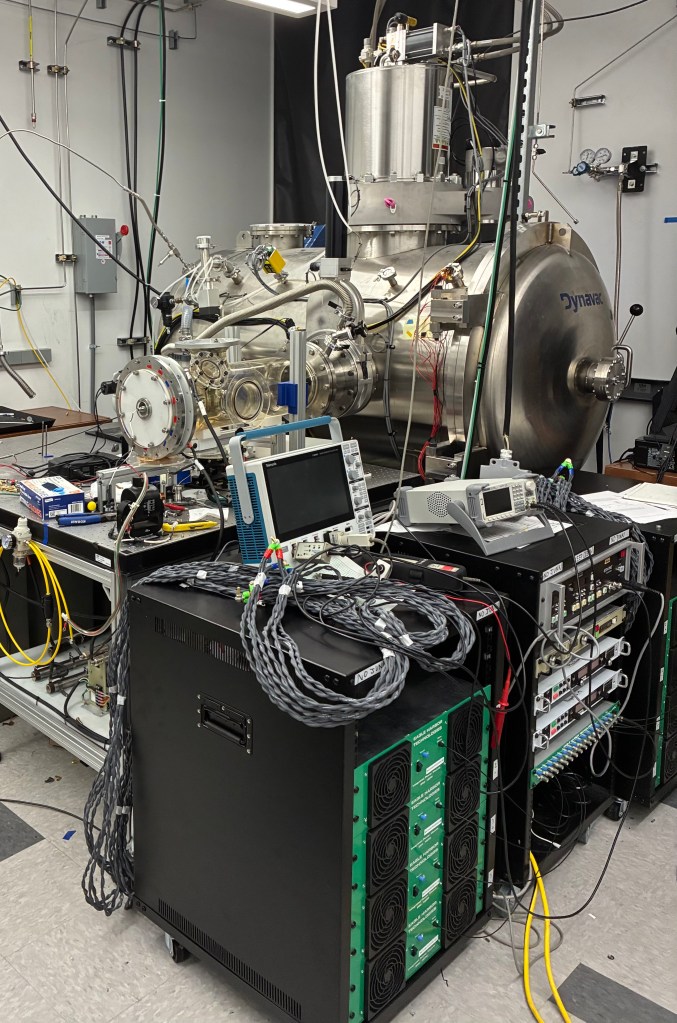

I was then assigned to work on building and integrating a capacitor bank to power the IPMs. I manufactured over 100 leads which directly connected the electrodes of the capacitors with the IPMs. This involved a similar process to the HV cables: I crimped, soldered, and heat-shrunk the terminals to the leads. I also actively tested the leads for continuity and material brittleness to ensure the solder was properly installed and did not cause mechanical issues.

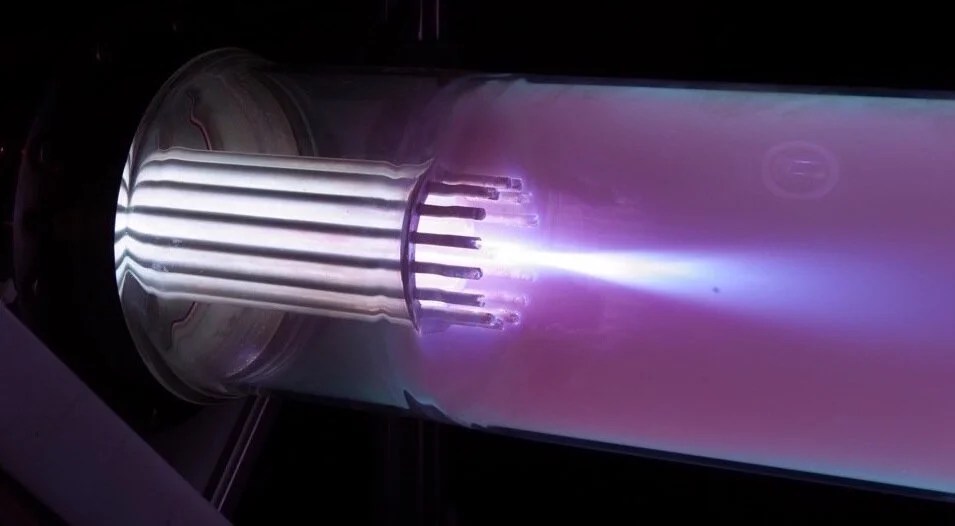

Once manufacturing was completed, we fully wired the capacitor to the IPMs and the IPMs to the thruster’s flanges. Upon completion, we began testing operations. I assisted in setting up the HPV-X High-Speed Camera and in footage gathering during the campaigns.